Aerospace Industry

Trusted CNC Machining Partner for Aerospace Innovation

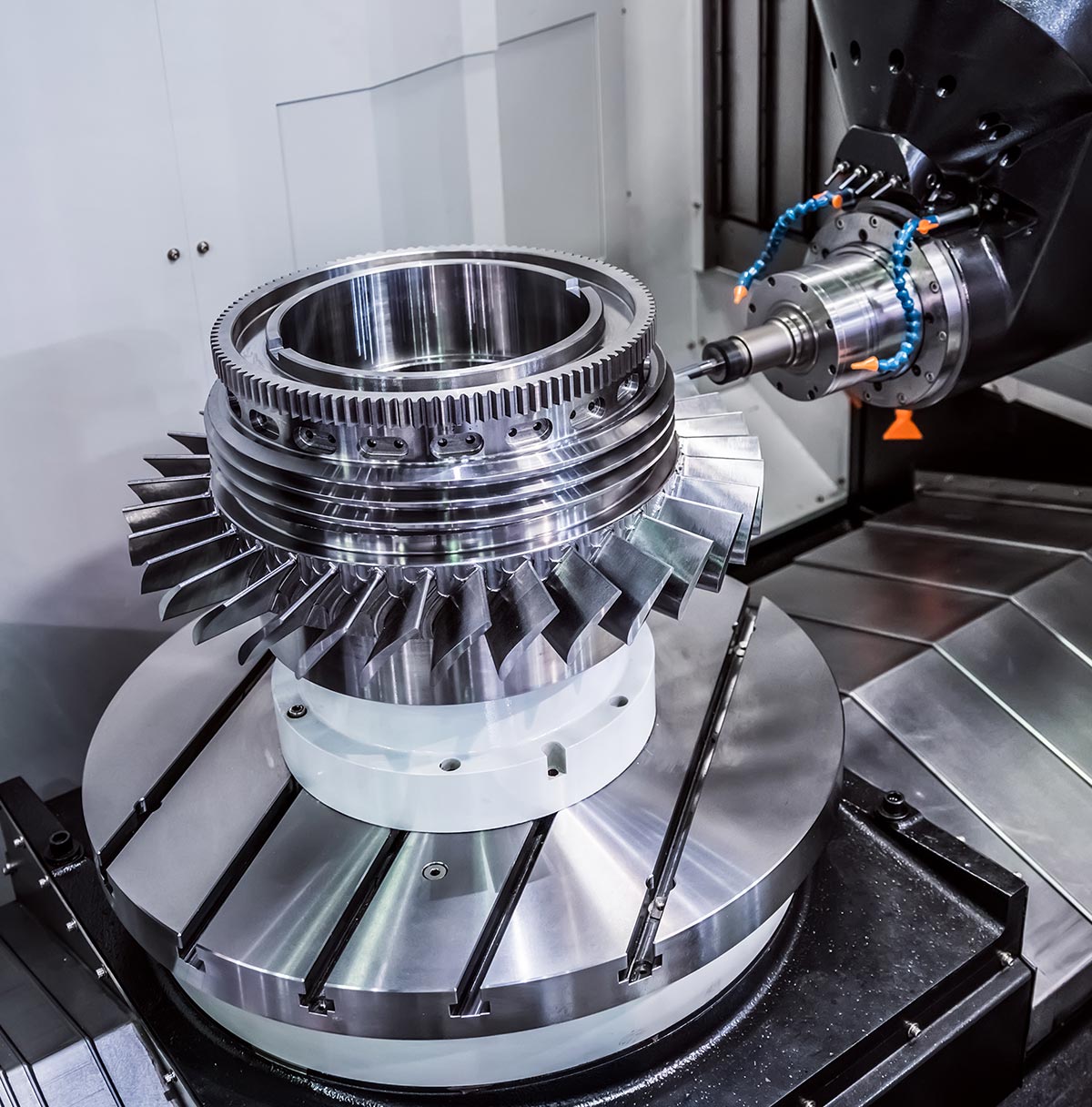

In the aerospace industry, precision isn’t optional — it’s mission-critical. At Hongwen, we deliver high-accuracy CNC machining services tailored to the complex requirements of aerospace components. From structural housings to engine parts and interiors, we produce mission-ready parts that meet tight tolerances, aerospace-grade standards, and demanding lead times.

We work with certified materials, advanced 5-axis CNC equipment, and strict inspection processes to ensure every part supports performance, safety, and compliance in flight-critical environments.

Aerospace Solutions

Why Aerospace Clients Choose Hongwen

- Tight Tolerances & Surface Quality

Achieve tolerances as low as ±0.01 mm with excellent finishes ideal for both interior and exterior aerospace parts. - Certified Materials & Documentation

We machine a wide range of aerospace-grade metals including aluminum alloys (7075, 6061), titanium, stainless steel, and engineering plastics — all traceable and certifiable. - Advanced Capabilities

3-, 4-, and 5-axis CNC machining, lathe turning, EDM, and complex part geometries supported. - End-to-End Quality Control

Every component undergoes dimensional inspection, surface evaluation, and can include CMM reports and First Article Inspection (FAI) documentation upon request.

Trusted by Aerospace Clients

Prototyping to Production – Scalable & Secure

Whether you need a single prototype for testing or a full batch of production-grade parts, Hongwen scales with your project. We support low-volume runs for design validation and short lead-time production for rapid response programs. With strict confidentiality protocols and traceability throughout our process, we’re trusted by aerospace clients to handle sensitive designs securely and efficiently.

Post-Processing for Aerospace-Grade Finishes

At Hongwen, we understand that function and finish go hand in hand. That’s why we offer a full range of post-processing services to meet aerospace visual, mechanical, and corrosion resistance standards.

Aerospace Applications We Support

Our CNC parts are used in:

- Aircraft interiors (mounting brackets, seat components, ventilation parts)

- Structural and airframe parts

- Satellite and UAV components

- Engine and turbine housings

- Ground support equipment

Materials Commonly Used in Aerospace CNC Machining

| Material | Use Case Example |

|---|---|

| Aluminum 7075 | High-strength airframe structures |

| Aluminum 6061 | Lightweight brackets and housings |

| Titanium | High-temperature, corrosion-resistant parts |

| Stainless Steel 17-4 PH | Engine parts and landing gear components |

| PEEK, PTFE | Lightweight, heat-resistant interior parts |

Industries We Serve:

Precision Across Diverse Sectors

Medical

CNC machining plays a vital role in the medical industry, producing high-precision components

Electronic

In the electronics industry, CNC machining is used to create intricate parts like connectors, enclosures, and heat sinks

Power Generation

CNC machining ensures the production of durable and high-precision components for power generation systems

Have a question? We’re here to help!

Have a question or need a quote? Contact us today and let’s discuss how we can bring your project to life with precision and expertise!