CNC Turning Service

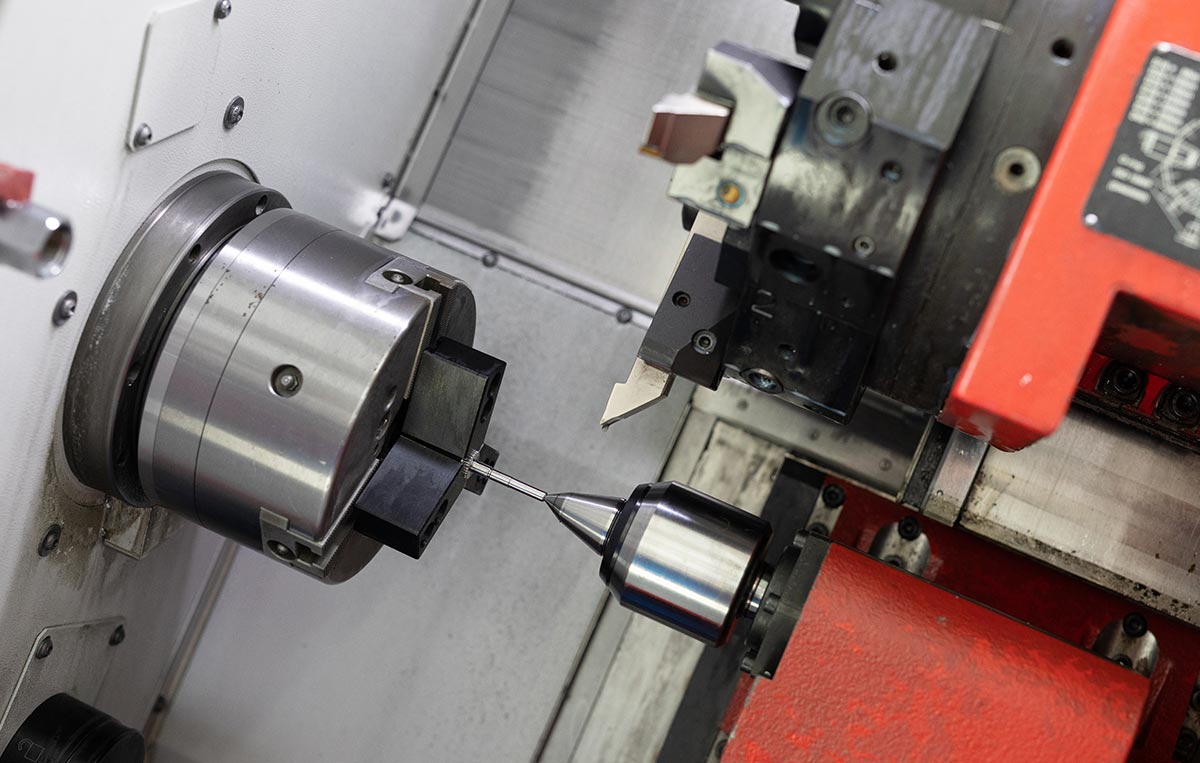

What Is CNC Turning?

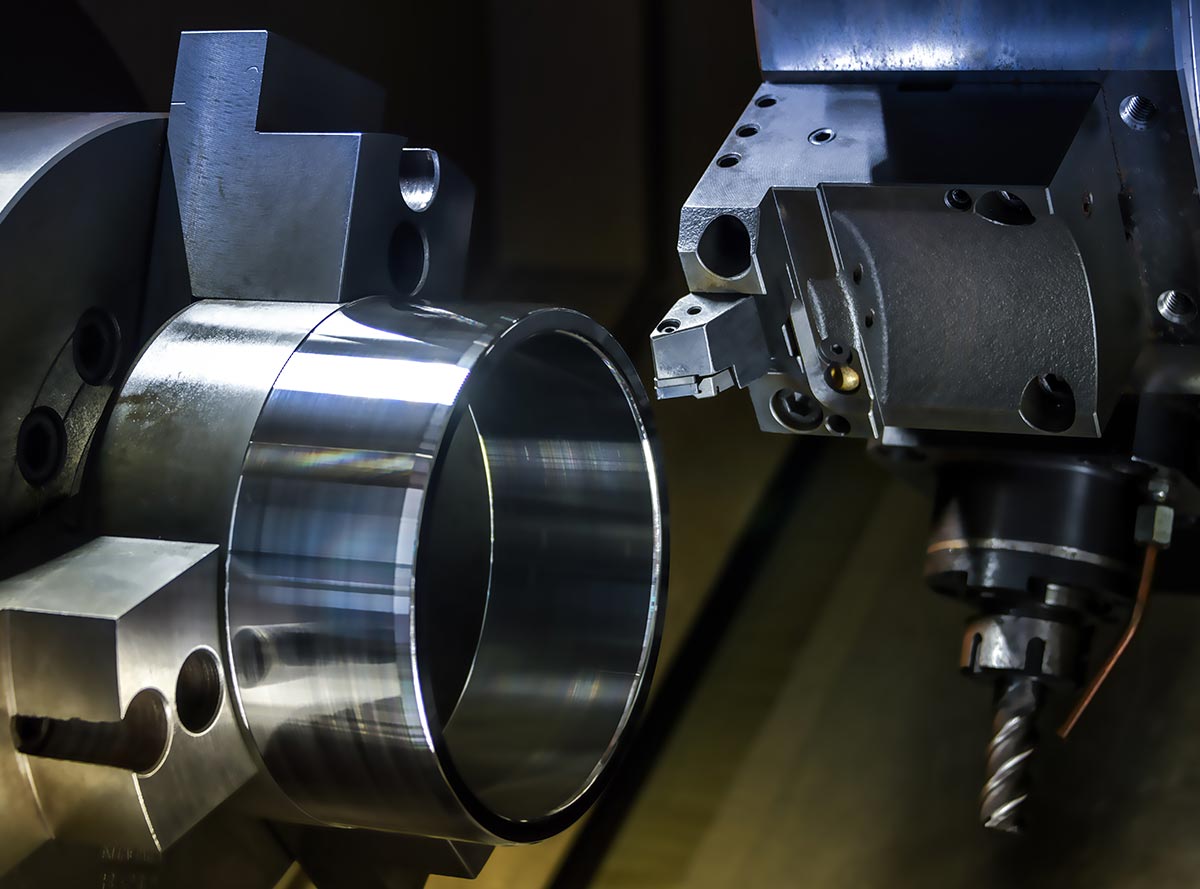

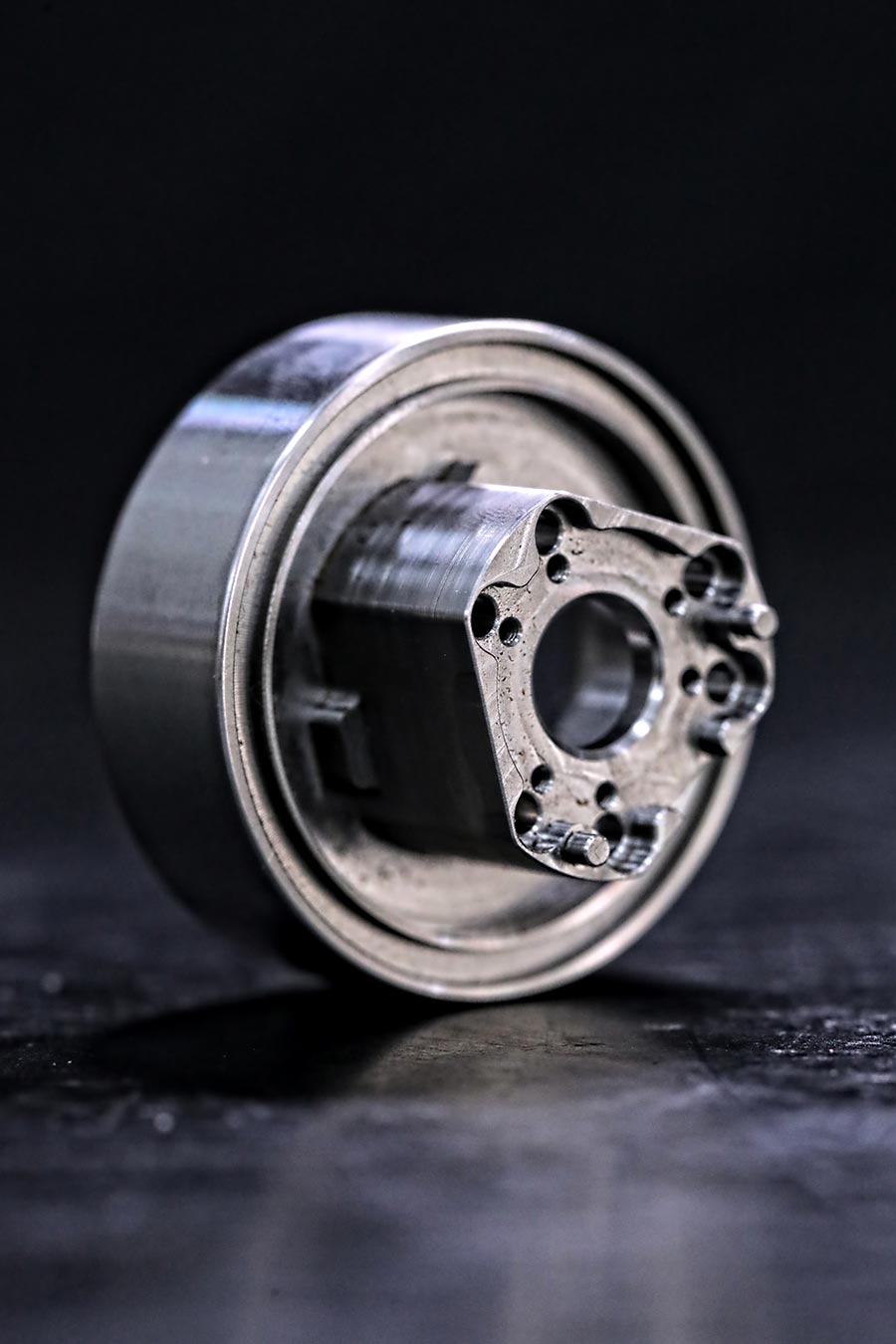

CNC turning is a precision machining process where a rotating workpiece is shaped using stationary cutting tools. Ideal for parts with rotational symmetry—like shafts, bushings, and fittings—it offers fast production cycles, tight tolerances, and cost-effective efficiency compared to milling

Why Choose Our Turning Solutions?

Precision & Quality

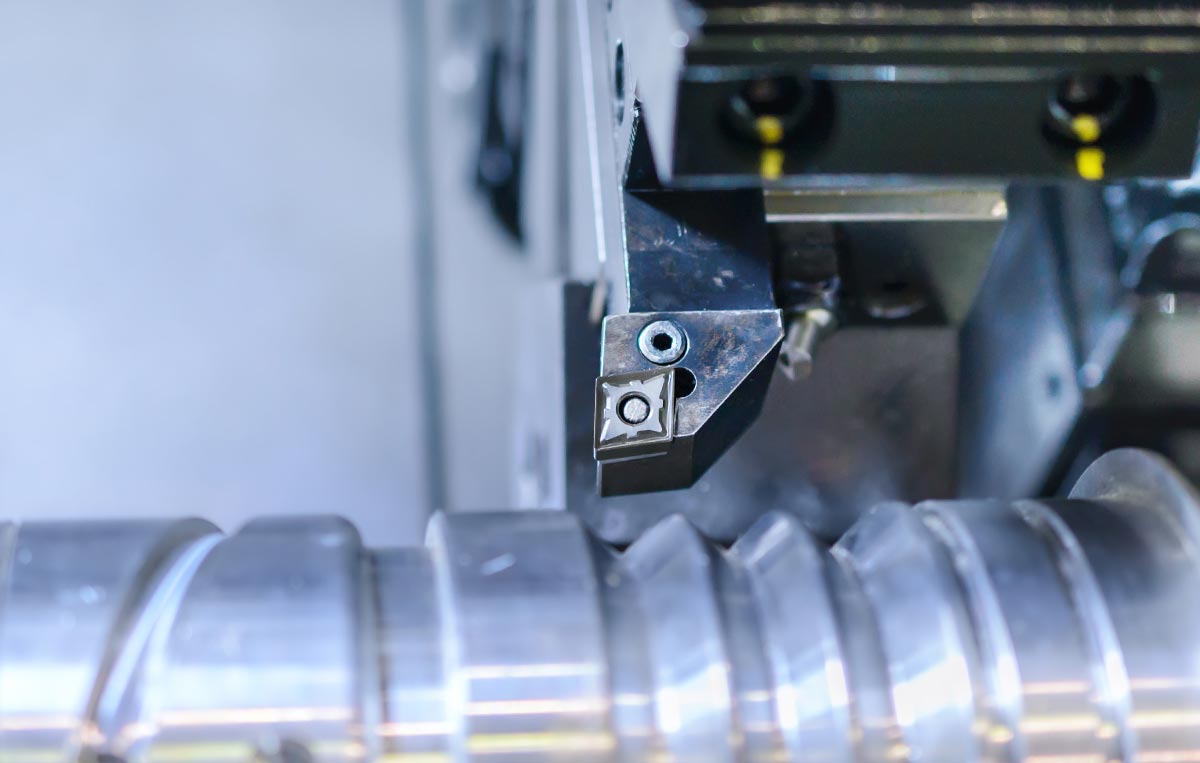

Achieve tight tolerances and smooth finishes thanks to advanced lathes—from conventional to Swiss-style and mill‑turn equipment .

Fast & Scalable Production

From rapid prototyping to high-volume runs, we deliver reliable parts with lead times as quick as 5 business days

Versatile Materials

We work with a broad range of metals (aluminum, stainless steel, tool steel, brass) and technical plastics to suit your project requirements .

Engineering Support & DFM

Our team reviews your CAD and technical drawings to optimize manufacturability, reduce costs, and safeguard design intent

Precision Tolerances

Tolerances for CNC Machining

| Capability | Details |

|---|---|

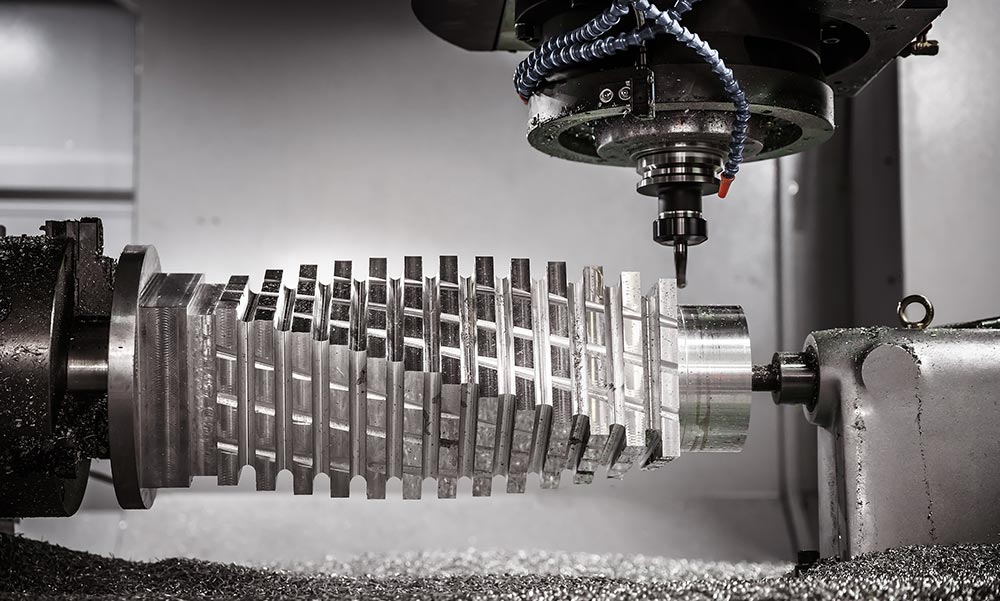

| Machines | 3‑axis lathes, mill‑turn centers, Swiss‑style precision machines |

| Tolerances | Down to ± 0.020 mm (± 0.001″) |

| Batch Size | Single prototypes to hundreds of units |

| Finishing | Smooth-as‑machined, bead‑blast, anodizing, plating options |

| Materials | Aluminum, steels, brass, copper, PEEK, ABS, Delrin, and more |

Our CNC machining process:

Upload CAD/Drawing

Submit your files to our expert team.

Engineering Review

We check for design for manufacturability and offer feedback

Quotation

Get pricing and timelines in minutes

Production Starts

Parts are machined, finished, and quality inspected.

Quality Control and Delivery

Receive parts within days, ready for prototype testing or production

Material & Process Interaction Chart

| Name | Applicable Materials | Colors | Can be applied with |

|---|---|---|---|

| Chem film or Alodine™ | Aluminum | Clear, gold | Media Blasting, Tumbling, Type II Anodizing*, Type III Anodizing*, Type III Anodizing with PTFE* |

| Anodizing | Aluminum | Clear, black, grey, red, blue, gold | Media Blasting, Tumbling, Alodine* |

| Black Oxide | Steel, Stainless Steel | Black | Media Blasting, Tumbling, Passivation |

| Electroless Nickel Plating | Aluminum, Steel, Stainless Steel | — | Media Blasting, Tumbling |

| Electropolishing | Steel, Stainless Steel | — | — |

| Hand Polishing | Acrylic | — | Enhanced cosmetic appearance |

| Media Blasting | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | — | All post processes except Electropolish and Powdercoat |

| Nickel Plating | Aluminum, Steel, Stainless Steel | — | Media Blasting, Tumbling |

| Passivation | Steel, Stainless Steel | — | Black Oxide, Electroless Nickel Plating, Zinc Plating, Tumbling, Media Blasting |

| Powder Coating Services | Aluminum, Steel, Stainless Steel | Black (20% or 90% gloss), white (20% or 90% gloss) | — |

| Tumbling | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | — | All post processes except Electropolish and Powdercoat |

| Vapor Polishing | CNC Polycarbonate (Clear, Black) | — | Enhanced cosmetic appearance, near optically clear applications |

| Zinc Plating | Steel, Stainless Steel | Clear: light blue coating, black: glossy black coating | Media Blasting, Tumbling, Passivation |

Real-World Success: Our CNC Solutions in Action

Explore our case studies to see how our precision CNC machining services have helped clients across industries achieve their manufacturing goals.

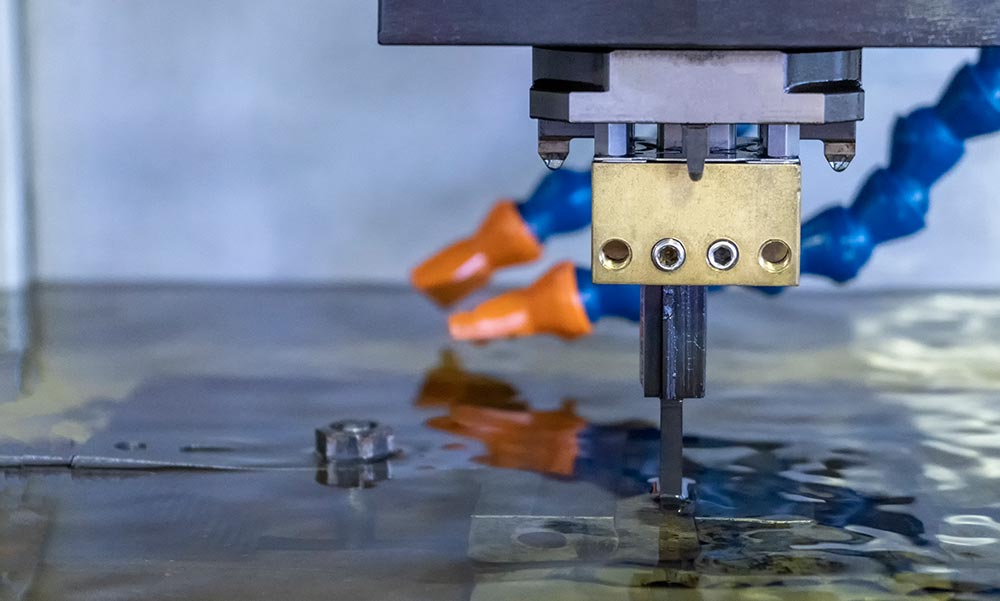

Advantages of CNC Turning

Our CNC turning service ensures high-speed, high-accuracy production for parts made from aluminum, steel, stainless steel, and plastics. We use advanced tooling and live tooling options to enable drilling, threading, and grooving in a single setup. This reduces turnaround time and enhances cost-efficiency — making it the preferred choice for automotive, aerospace, medical, and industrial components.

Our Services:

Precision Solutions Tailored to Your Needs

Milling

Precision machining process used to create complex shapes and parts by removing material with rotating cutters. Ideal for both high-volume and intricate designs.

Drilling

Used to create round holes in parts by using a rotating drill bit. Ideal for producing holes of various sizes and depths in a wide range of materials.

Tapping

A process that creates internal threads in a hole, allowing for secure fastening. Perfect for manufacturing components that require threaded connections.

EDM

A precision machining method that uses electrical sparks to shape hard metals and complex geometries. Ideal for intricate and delicate components.

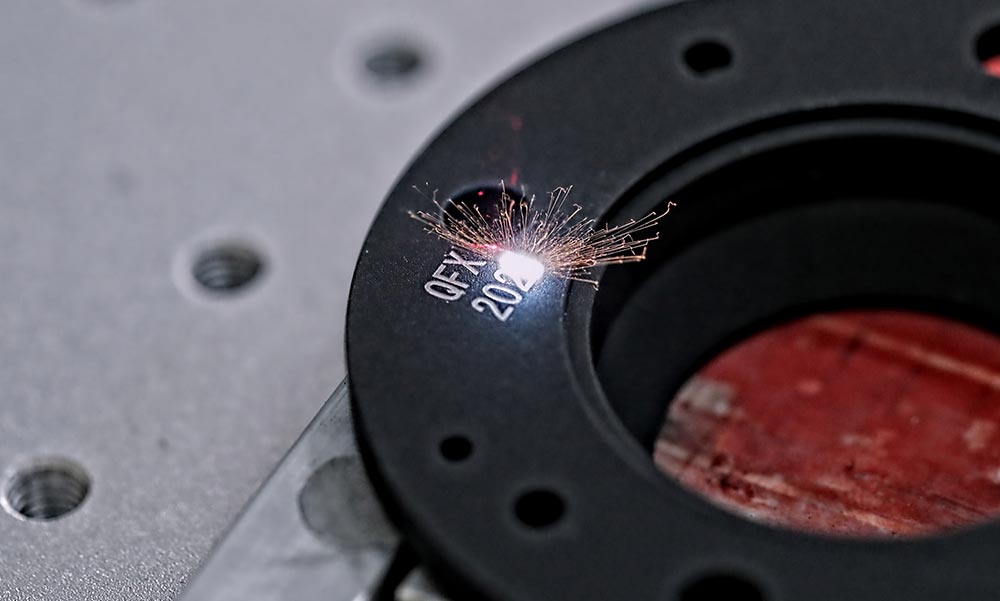

Laser Marking

Uses a focused laser beam to etch text, logos, or codes onto parts. Offers high precision, durability, and is widely used for identification and branding.

Finishing

Post-machining processes like polishing, coating, or deburring to achieve the final surface quality and desired finish, ensuring parts meet exacting specifications.

Industries We Serve:

Precision Across Diverse Sectors

Medical

CNC machining plays a vital role in the medical industry, producing high-precision components

Electronic

In the electronics industry, CNC machining is used to create intricate parts like connectors, enclosures, and heat sinks

Power Generation

CNC machining ensures the production of durable and high-precision components for power generation systems

Aerospace

CNC machining is essential in the aerospace industry, manufacturing high-precision, lightweight components

Have a question? We’re here to help!

Have a question or need a quote? Contact us today and let’s discuss how we can bring your project to life with precision and expertise!